Bearings are mechanical components used to reduce friction between two moving parts, facilitating smooth and efficient motion. They are essential in a wide range of machines, from engines to industrial equipment, to support loads and reduce wear and tear during operation.

Key Features:

- Friction Reduction: Bearings minimize the friction between moving parts, which reduces energy loss and enhances efficiency.

- Load Support: Bearings help distribute loads evenly, preventing direct contact between moving parts and reducing wear.

- Durability: Made from hard-wearing materials, bearings are designed to withstand high loads, speeds, and harsh conditions.

- Precision: Bearings ensure smooth motion, helping parts stay in proper alignment, improving performance and accuracy.

Types of Bearings:

- Ball Bearings:

- Structure: Composed of small spherical balls placed between two smooth rings (inner and outer races).

- Function: Most common type, used for low to medium load applications with moderate speed.

- Applications: Found in motors, automotive, machinery, and various household appliances.

- Roller Bearings:

- Structure: Similar to ball bearings but with cylindrical rollers instead of balls.

- Function: Can handle higher loads than ball bearings and are often used in heavy-duty applications.

- Applications: Used in construction machinery, conveyors, and automotive wheel hubs.

- Needle Bearings:

- Structure: A type of roller bearing where the rollers are long and thin, resembling needles.

- Function: Designed for applications where space is limited but high load capacity is needed.

- Applications: Common in automotive engines, transmissions, and power tools.

- Tapered Roller Bearings:

- Structure: Contain conical rollers that contact both the inner and outer races at an angle.

- Function: Designed to handle both radial and axial loads, making them ideal for applications involving heavy-duty and high-speed operations.

- Applications: Widely used in wheel bearings, trucks, and industrial machines.

- Thrust Bearings:

- Structure: Specifically designed to handle axial loads (forces parallel to the shaft).

- Function: Used to support rotating shafts subjected to axial pressure.

- Applications: Found in automotive applications, such as in gearboxes and motors, and industrial machinery.

- Magnetic Bearings:

- Structure: Uses magnetic fields to levitate and stabilize rotating parts without physical contact.

- Function: Completely eliminates friction, offering high-speed and low-maintenance solutions.

- Applications: Found in high-speed machinery, like turbines and certain types of compressors.

- Fluid Bearings:

- Structure: Use a thin layer of pressurized fluid (oil or air) to support the moving parts.

- Function: Provide frictionless motion, reducing wear and extending service life.

- Applications: Common in precision machinery, such as in large generators and heavy industrial equipment.

Materials:

- Steel: Most common material for bearings due to its durability, strength, and resistance to wear.

- Ceramic: Used for high-performance applications where low friction and high-speed capabilities are required.

- Plastic: Used in lightweight applications where corrosion resistance is needed and the load is relatively low.

- Stainless Steel: Offers additional resistance to corrosion and is often used in harsh environments.

Functions:

- Load Distribution:

- Bearings help evenly distribute the load between the moving parts, preventing direct contact and reducing wear on the components.

- Friction Reduction:

- By minimizing friction, bearings help prevent overheating, reduce energy loss, and allow for smoother motion, increasing efficiency.

- Smooth Motion:

- Bearings ensure that parts like shafts, wheels, and gears move smoothly, reducing vibration, noise, and the risk of mechanical failure.

- Alignment:

- Bearings keep moving parts aligned, preventing misalignment that could lead to premature wear, increased energy consumption, or system failure.

Applications:

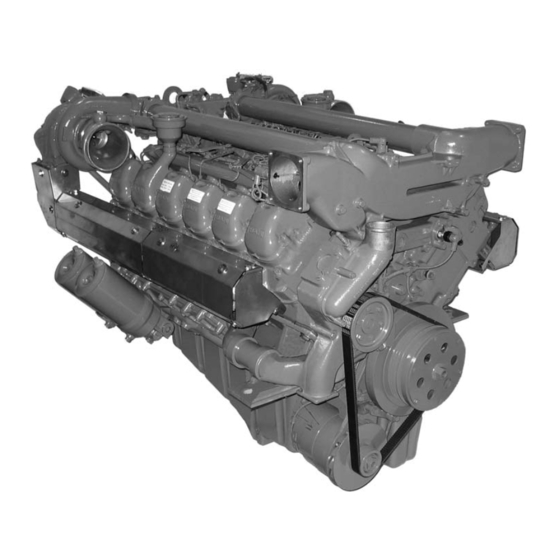

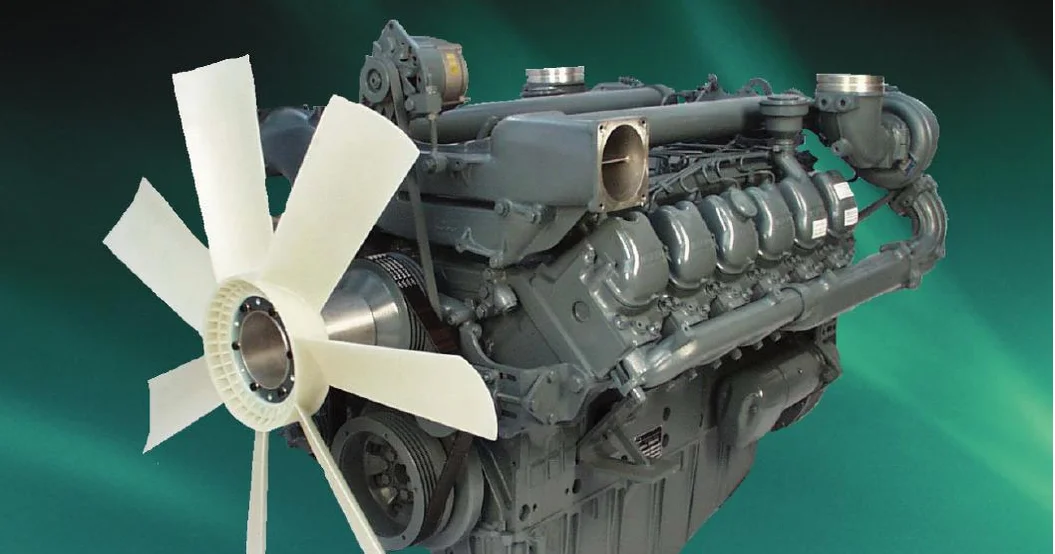

- Automotive Industry: Bearings are found in engines, transmissions, wheels, and suspension systems.

- Industrial Machinery: Bearings support rotating equipment such as motors, pumps, and conveyors.

- Consumer Electronics: Bearings are found in hard drives, fans, and power tools to ensure smooth operation.

- Aerospace: Bearings are crucial in aircraft engines, landing gear, and navigation systems.

- Renewable Energy: Bearings are essential in wind turbines to support and stabilize the rotor.

Importance of Bearings:

- Efficiency: By reducing friction, bearings improve the energy efficiency of machines and engines, helping them run smoother and longer.

- Reliability: High-quality bearings increase the reliability and performance of mechanical systems by minimizing the risk of breakdowns due to friction or wear.

- Cost-Effective: Bearings extend the lifespan of machinery and components, reducing the frequency of repairs and maintenance costs.

- Precision: Bearings ensure the precise movement and alignment of machine parts, which is critical in high-accuracy applications.

Bearings are fundamental components in modern machinery, ensuring smooth, efficient, and reliable operation across various industries. Whether in a simple household fan or a complex industrial machine, bearings reduce friction, support loads, and extend the lifespan of equipment.

Reviews

There are no reviews yet.